DeFacto Design

I founded DeFacto with architect Leandro Rolon in 2015. Located in the heart of Beijing, DeFacto was a Design Studio with the reputation of having an experimental and research driven 3D printing focus. Originally starting with education in design and 3D printing, we noticed a gap on the market between the rapid emergence of 3D printing hardware and its actual applications. As Designers, we aimed to creatively fill this void with our ideas and creations.

Selected Projects:

FOOD 3D PRINTER

The Food 3D Printer was one of our in-house developed products under our gastronomy focused brand “The 3D Food Company”. Fully designed and engineered in our studio this first iteration of food printer was targeted towards high cuisine and use in restaurants. We printed everything from foie gras to tiramisu and fries. Our goal was to give chefs another tool in their tool box to create memorable food experiences, enhance customization options and make kitchen processes more efficient. Together with great chefs like Aniello Turco (awarded with Michelin star at Four Seasons Beijing) we tested and iterated on our machine and fine-tuned its user experience. We also partnered with Elzelinde van Doleweerd and her up-printing food project (dezeen article), which aims to reduce food waste and created the first 3D printed dinner in China. (article)

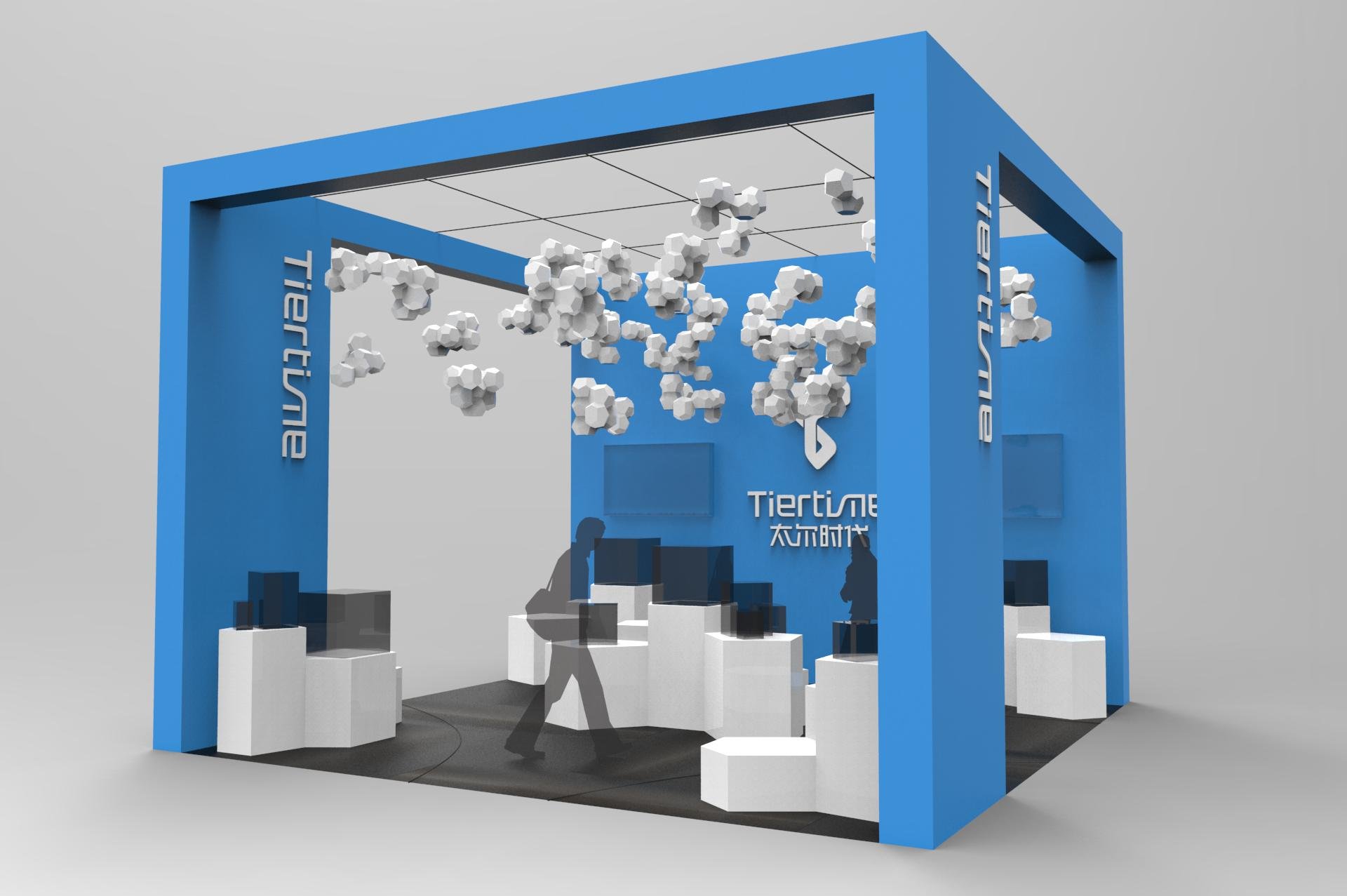

RISE PAVILION

In 2016 DeFacto was hired by RISE (english education company based in China) to design and build a structure that would be awarded the Guinness World Record for largest 3D printed structure. Our main concern while designing the Guinness pavilion was controlling the environmental impact of 3D printing 1.87 tons of plastic. As a result the design was fully driven by maximizing the after-use and up-cycling potentials. It was important to the team that the structure had a use beyond the life-span of the pavilion. Thus leading to the project’s central theme, “A pavilion made up of 5000 lamps.” The building blocks of the pavilion could easily be turned into lamp shades and were sent to RISE students in China.

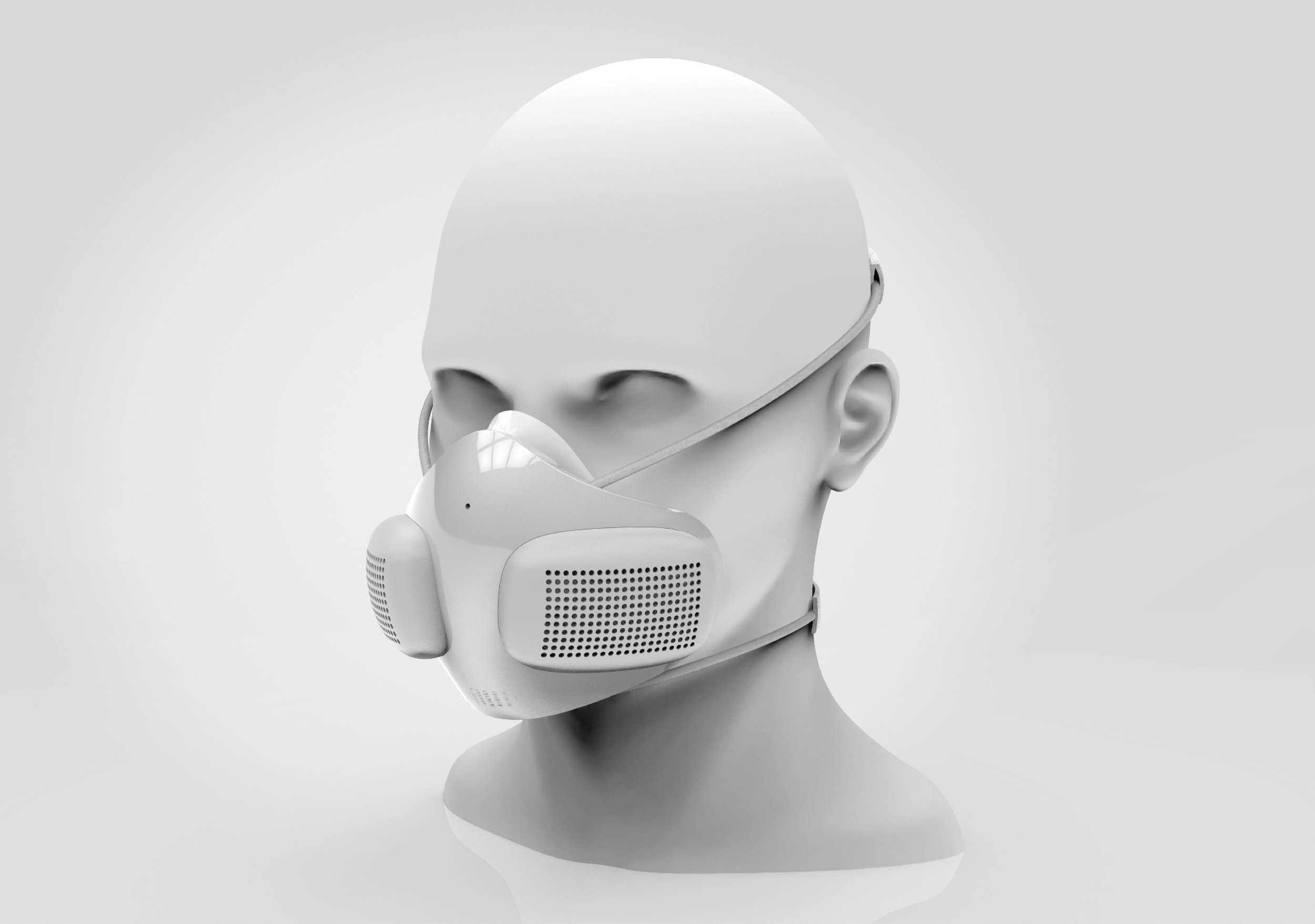

ATMOBLUE

A smart, wearable air purifier that blocks 99.9% of bacteria, pollution, smoke and allergens. We designed, prototyped and developed ATMOBLUE for our client Blueskylabs in 2017/18. Our studio was the design team for the product for initial design iterations, user testing and prototyping all the way through manufacturing. It was our first product that went into mass production. ATMOBLUE was awarded a RED DOT Design Award in 2018.

Learn more about the product at atmoblue.com

3D Printed Fashion

This 3D printed dress was one of the products that came out of our research and talk series into 3D printed and laser cut fashion. During this series we explored different designs to make textiles with digital manufacturing tools such as 3D printers. Bringing together engineers and 3D printing experts with fashion designers and architects we aimed to explore the applications of this technology in the fashion industry now and in the future. We always loved to connect with industry experts (be it fashion or culinary) and explore what this new tech could mean to them and their field of work.

“Queen Bee” (the dress) was exhibited at the Beijing Design Week in 2015. The top was SLS printed nylon and was designed to fit with different “bottoms”. Wedding dress, Qipao (Chinese traditional dress form), etc could be fit with a top that could be highly customized to the clients wishes (body measurements, color, pattern, even material).

GALLERY